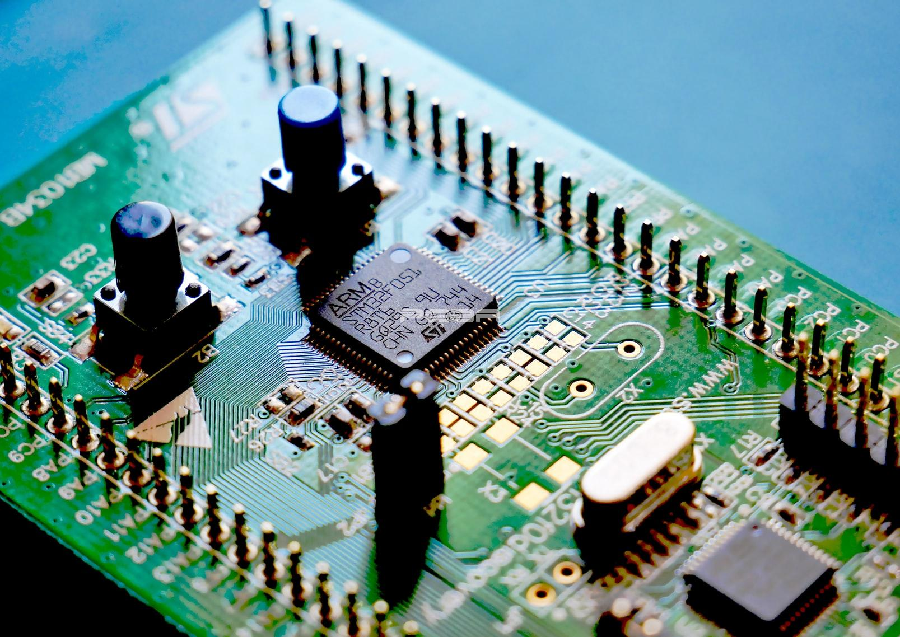

Over many decades, printed circuit boards (PCBs) have slowly grown into a small, efficient, and essential component of a wide range of machinery, automobiles, computing terminals, PLCs, and other electronic equipment. They’ve also had a massive impact on introducing innovations, technologies, and inventions in the worldwide electronics sector. Their small size and excellent reliability highlight the complexity required to make high-quality PCBs in electrically connecting individual electronic components of an electronics design. Surface mount technology (SMT) is the most used PCB assembly approach today, and it is a significant improvement over prior assembly techniques like through-hole assembly. SMT assembly is now widely regarded as the gold standard of PCB assembly techniques.

SMT has supplanted conventional manufacturing processes as the primary method of producing China PCB for a variety of reasons, including:

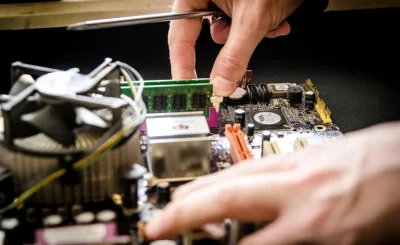

Before the widespread use of SMT assembly, point-to-point and through-hole assembly were used; however, these techniques took a long time because assemblers had to solder pads to the PCB’s frame and connect wires, which not only took longer to solder but also changed the way energy was transmitted throughout the PCB. SMT eliminates these issues by attaching components to the PCB’s surface rather than through-hole connection connections. This basic idea allows PCBs to be made using automation, which saves time.

Reduces Assembly Costs: Traditional PCB assembly takes a lot longer than automated SMT assembly. As a result, China PCB used to be more expensive to create than it is now, thanks to SMT assembly. Furthermore, previous assembly procedures made making a handful of PCBs for low-quantity or prototype PCBs, which design engineers, prohibitively expensive, frequently require. On the other hand, SMT assembly pushes down production costs to highly appealing price points due to automation and the flexibility to plan the creation of a range of low-quantity PCBs at the same time. Customers worried about prices should always check that a PCB assembly service can do automated SMT assembly.

Enhanced Usability: PCBs developed for SMT assembly contain smaller components than in the past, resulting in a PCB that is more compact, sleeker, and energy-efficient as a whole. Because of these benefits, modern PCBs may be utilized in a more extensive range of devices, such as handheld and laptop computers, smartphones, and machines that demand a flat, compact PCB control board rather than one with large dimensions. SMT-manufactured PCBs have received widespread acceptability due to these factors, from electronic circuit design experts to OEM machinery designers, among others.

ChinaPCBOne Technology LTD. is the author of this article on PCB Assembly. Find more information, about China PCB.